Phone: +86-18522819855 +86-17692710196

E-mail:andi@yeweiyibiao.cn,754183837@qq.com

Address:No. 7, Yinhai Road, Economic Development Zone, Wei County, Hebei Province, China

©2019 XUKANG All rights reserved

PRODUCT DETAIL

Product name

HF Forged steel offset boiler Reflex Glass Plate Level Gauge

Basic information

Detailed parameters

Product number

UI-CV-F-HF

Affiliated category

Glass plate level gauge

Heat

Quantity

-

+

360° display

Download product manual

I want to inquire price

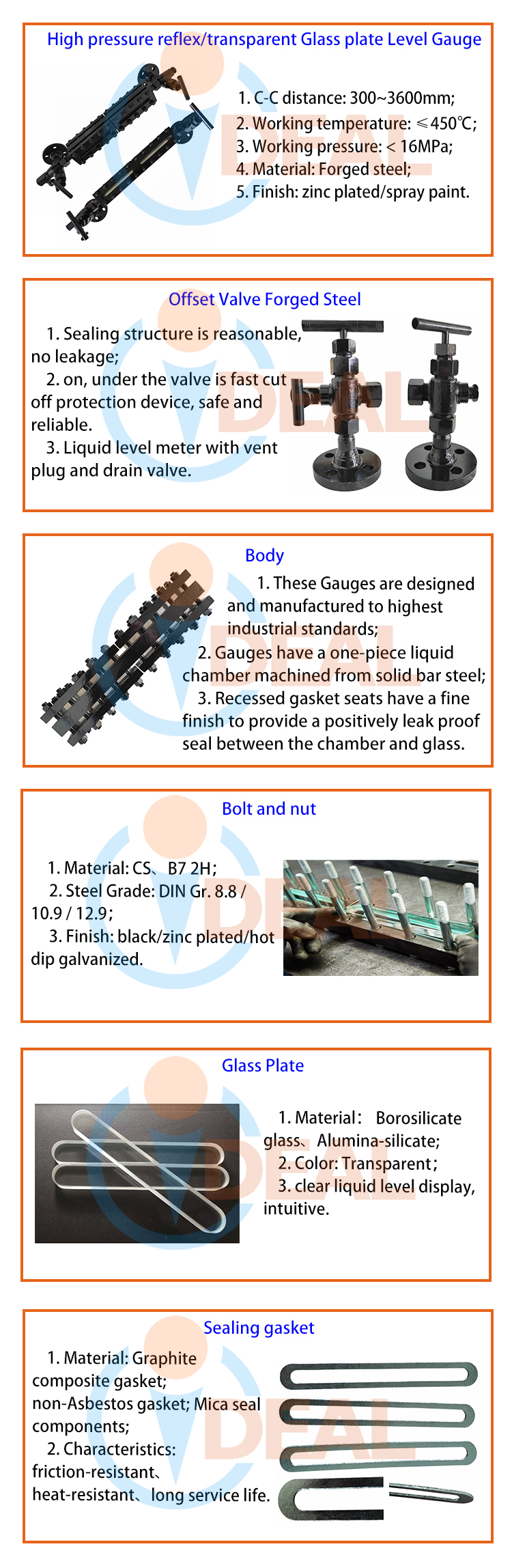

Reflex gauges have a single piece of glass, mounted on one side of the chamber. This piece of glass is flat on the outside, and has a series of prisms on the inside, facing the process fluid. When light strikes the portion of the glass covered by a liquid, the light is reflected from the back of the chamber. This area appears “black”. When light strikes the glass where no liquid is present, the prisms reflect the light directly out of the gauge. This area appears “silvery”. Reflex gauges provide an excellent way to measure clear, or difficult to see fluids. The “silvery”/”black” interface is easy to see from several feet away.

Features:

1. They do not need electrical power to operate. This can be a great advantage in the case of a power outage.

2. Simple to install – no calibration is necessary.

3. Can be used as a reference to check, or calibrate, other level technologies.

4. Pressure rating from vacuum to 4Mpa.

5. Temperature rating from -20℃ to 450℃

7. Not affected by the chemical or electrical properties of the process liquid.

8. Specific gravity, dielectric, conductivity, surface turbulence, vapor, foam, etc. no longer needs to be considered.

The classification and scope of use of glass level gauges are as follows:

1. Heat-tracing glass plate level gauge: mainly used for the occasions where the measured medium needs heat preservation;

2. Frost-proof glass plate level gauge: mainly used for occasions where the operating temperature of the medium under test is -196~0℃ and the glass is prone to frosting;

3.Glass plate level gauge without blind area: mainly used in situations where continuous observation is required and blind areas are not allowed in the visual range;

4. Two-color glass plate level gauge: mainly used for occasions where the medium is colorless and transparent liquid and liquid level is not easily observed;

5.Uv - proof glass plate level gauge:mainly used for the occasions where the measured medium is afraid of ultraviolet light;

6. Wide liquid chamber glass plate level gauge: mainly used for occasions where the viscosity of the measured medium is relatively large or the volume of the instrument is relatively large;

7. Illuminating glass plate level gauge: mainly used for night observation.

Keywords

Forged steel Reflex Glass Plate Level Gauge

offset boiler Reflex Glass Plate Level Gauge

High pressure Reflex level gauge

Previous

No blind area Directly Reading Reflex Glass Level Meter

Next

HT Forged steel high pressure glass plate level gauge